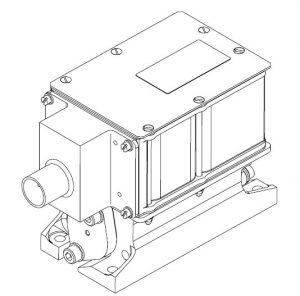

With two AAI hydraulic rigs, a dedicated stab trim ballscrew test rig and Fuel boost pump test cell the mechanical workshop is well equipped for a wide scope of work.

Add to this the specialist test equipment manufactured in house by the Research and Development team to meet and exceed OEM requirements and you have a one stop shop for your mechanical and actuation needs.

Repairs include, but are not limited to:

- Swivels

- Locks and Latches

- Door Snubbers

- Flap Ballscrew Actuators

- Stab Trim Avtuators

- Thrust Reverser Actuators

- Spoiler Actuators

- Electrical Actuators

- Rudder PCU’s

- Uplocks

- Landing Gear Actuators

- Landing Gear Door Actuators

- Oil Pumps

- Fuel Pumps

As with all repairs, CRS Technics are constantly striving to improve reliability and extend life, and on hydraulic and mechanical equipment in addition to developing our own repairs and parts, CRS Technics look to the market for PMA availability. Once a suitable PMA part is selected CRS Technics Research and Development team in conjunction with 21j assess the benefits of the available material. Once proven to be a superior part, CRS Technics would offer the findings to the customer as an option to improved reliability going forward and warrant the component accordingly. In addition CRS Technics can assist with IPC implementation of any alternate parts used.

Case study:

CRS Technics have multiple repairs available across flap interconnecting struts which receive multiple damage due to the harsh conditions they are subjected too.

- Fault – oil ingression into sheathed harness, damaging internal wiring.

- Solution – employ replacement PMA sheath with rubberised coating to repel ingression.

- Fault – Wear on body through chafing of armoured sheath on body.

- Solution – Tungsten Carbide coating applied in area of chafing.

- Fault – Proximity Sensor not failure (High Cost Component)

- Solution – Proximity Sensor Repair Scheme created and implemented.

As always, no Part 21j approved repairs or EPA/PMA parts would be fitted without prior authorisation from the customer, and any such repairs and/or parts would be used in conjunction with extended warranty terms.

With a wealth of experience, detailed reverse engineering ability, in-depth analysis and testing in partnership with an EASA Approved 21j Organisation, CRS Technics can repair out flaws and faults as part of an enhanced repair on the component and offer an extended warranty.