CRS Technics offer a wide range of repair services across a multitude of electrical components, from electronics to power generation. With specialist test equipment both manufactured in house by their Research and Development team to meet and exceed OEM requirements and dedicated test rigs/benches from well-respected tooling manufacturers such as Avtron/Testek and AAI/ACL technologies CRS offers a one stop shop for electrical components.

Repairs include, but are not limited to:

- Lights and lighting systems (internal and external)

- PSU’s

- Window Heat Controllers

- Ignition Systems

- GCU and BCU,

- Emergency lights,

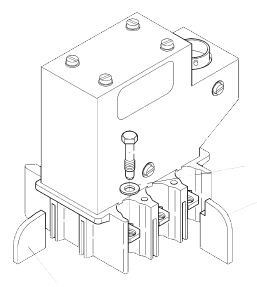

- Contactors

- Fire Detection Sensors

- Temperature sensors

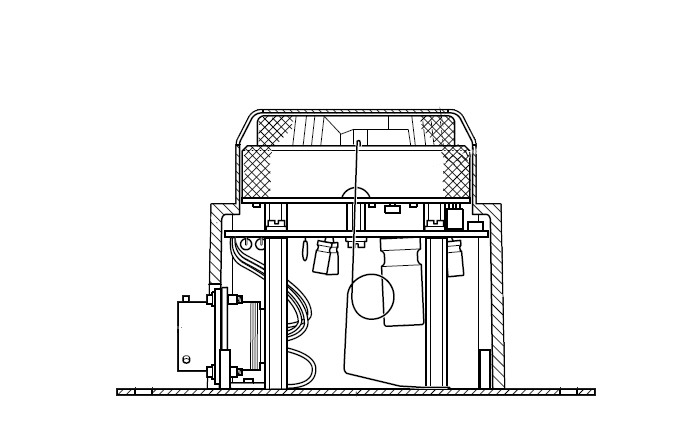

- Power Drive Units

- Electrical Actuators

- Landing Gear Looms / Harnesses

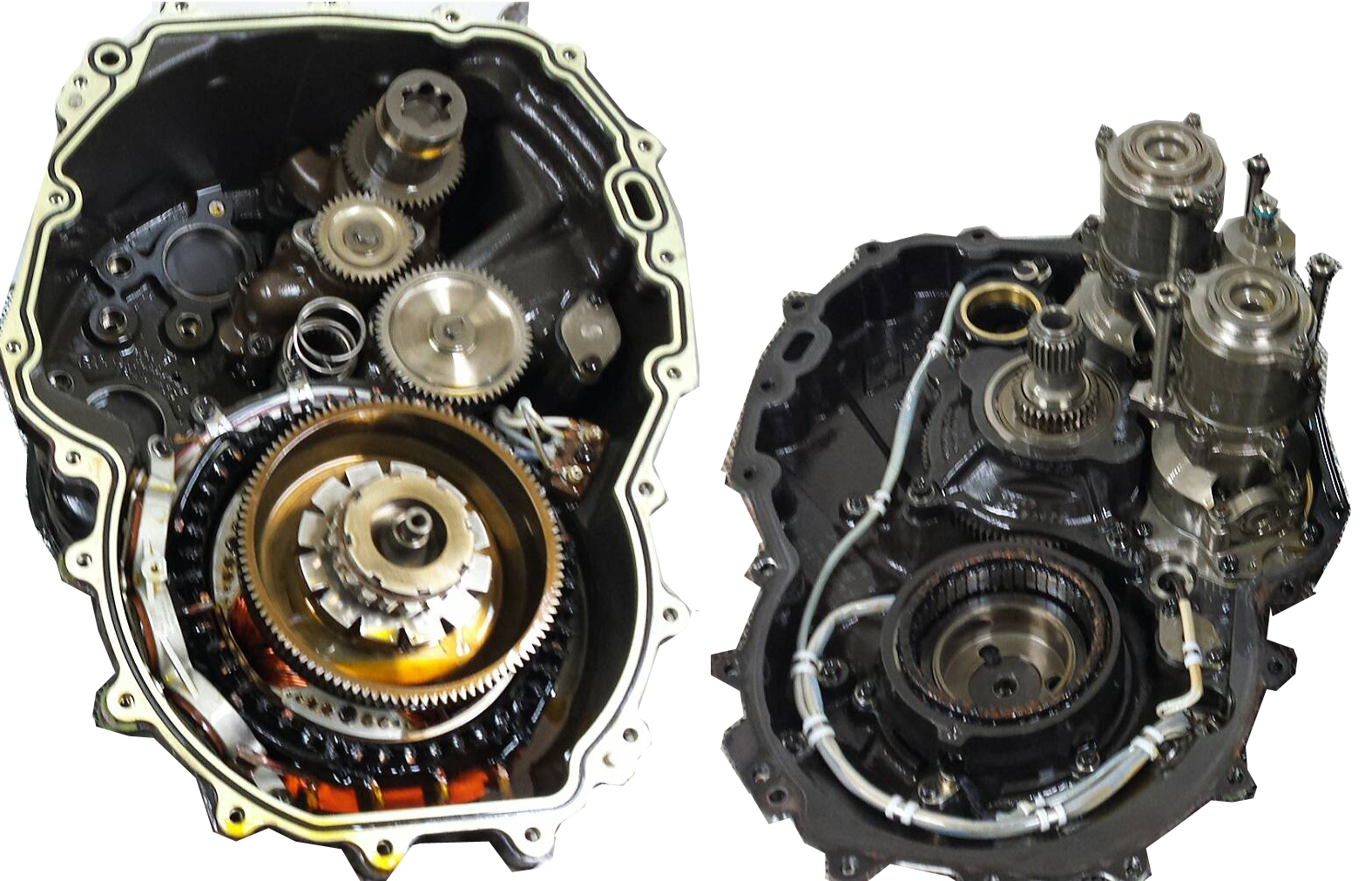

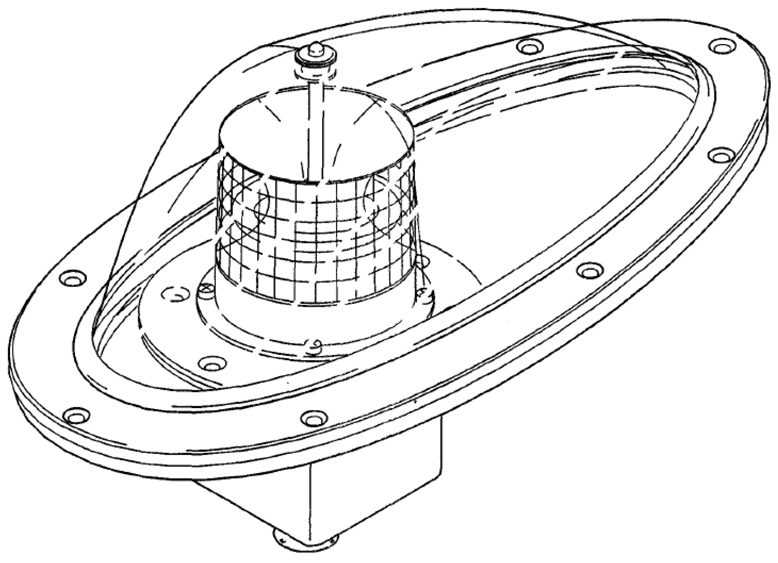

- Generators (APU / Engine)

- CSD’s and IDG’s

As with all repairs, CRS Technics are constantly striving to improve reliability and extend life. So as part of our internal reliability monitoring CRS Technics continually look to develop enhanced repairs alongside our 21j approved company, or develop more reliable 21g piece parts for use in repair which CRS Technics can then offer to customers for prior approval.

A small sample of CRS Technics enhanced repair activity includes:

- Detailed repairs available for Airbus electrical contactors, which would otherwise be a test only item.

- Detailed repairs on proximity sensors, high cost consumable.

- Repairs to Captain Seat Actuator control PCB, high cost consumable.

As always, no Part 21j approved repairs or EPA/PMA parts would be fitted without prior authorisation from the customer, and any such repairs and/or parts would be used in conjunction with extended warranty terms.

With a wealth of experience, detailed reverse engineering ability, in-depth analysis and testing in partnership with an EASA Approved 21j Organisation, CRS Technics can repair out flaws and faults as part of an enhanced repair on the component and offer an extended warranty.